Investment frenzy driving down margins in BOPP film

June 13, 2018In the space of two years, the bi-axially oriented polypropylene (BOPP) film industry has moved from a scenario of modest capacity growth and improving margins to one where it seems everyone is struggling to make money thanks to another frenzy of investment in high-capacity BOPP film lines around the world. That’s according to analysis from Applied Market Information (AMI; Bristol, UK). While demand for BOPP film continues to grow “respectably,” it is not advancing sufficiently to absorb capacity increases without causing a margin fight to either grow or maintain market share.

AMI noted that companies “with high debt andor aging assets that cannot match the efficiency of modern equipment are particularly vulnerable. The new capacity increases are expected to drive rationalism of older capacity andor merger and acquisition activity.” While profitability remains a challenge for the industry, the market continues to expand, with volumes growing by nearly 5% in 2017, the highest rate since 2012, driven by improving fundamentals in the global economy. This increased the global market to more than 8 million tons. The five-year compound annual growth rate for 2012 to 2017 was 4%, which has added just over 1.5 million tons of demand, said AMI.

BOPP film demand, AMI Consulting

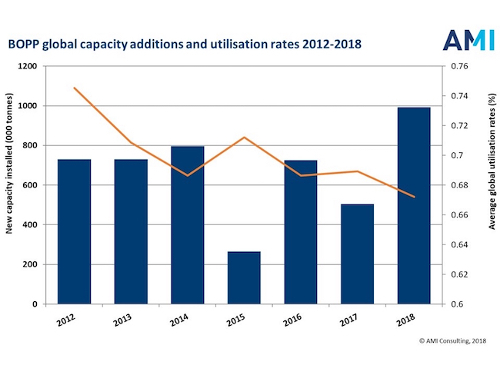

These strong underlying fundamentals are driving continuous investment in new capacity—more than 3 million tons of BOPP production were added globally between 2012 and 2017. Nearly two-thirds of that went to China, which accounts for nearly half of global capacity and demand. “For the first time its two leading producers, China Soft Packaging and Gettel Group, topped the world rankings in volume terms, although Taghleef and Jindal Films remain the leading players by turnover,” according to AMI Consulting.