Aluminium Thickness Uniformity in Vacuum Web Metallizing:

January 16, 2025The demand for faster vacuum metallizing processes combined with thicker aluminium coatings has sparked a renewed focus on achieving uniformity in the deposited layers across both the width and length of a moving film web. In response, vacuum web metallizers have been re-engineered, with particular emphasis on optimizing the evaporation source design. Modern systems now utilize inline optical density monitoring to control the evaporation rate and line speed via advanced computer-controlled closed-loop feedback systems.

This article explores how MathCad simulations are utilized to predict the effects of evaporation boat condition on film uniformity during vacuum web metallizing. Additionally, it investigates the interaction between vapor clouds from multiple boats and comparing simulation results to experimental data. The findings show a strong correlation between simulated and experimental results, offering valuable insights that can also predict the impact of source-to-film distance and vacuum level on aluminium thickness uniformity.

1. Introduction:

As the demand for high-speed vacuum metallizers grows, particularly in flexible packaging and other high-performance applications, achieving exceptional aluminium thickness uniformity has become more critical than ever. For instance, cutting-edge equipment for packaging applications must maintain a line speed of over 10 m/s, with a coating thickness variation of less than ±5%. In solar window film applications, uniformity must stay within ±2%.

The efficiency of these machines directly impacts the quality of the metallized film, where uniformity plays a pivotal role. Poor uniformity can result in defects such as banding, which severely affects product quality. Several factors influence this uniformity, including the film’s surface energy, the vacuum level in the evaporation zone, the design and condition of the evaporation boats, and the control of the evaporation rate.

At Idvac, we’ve harnessed the power of MathCad simulations to predict and improve the uniformity of the metallized film by analysing the impact of aging conditions on evaporation boats. Through these simulations, we also examine the interaction between vapor clouds from multiple boats and validate the results with experimental data. The findings demonstrate a close match, offering valuable predictive insights into the effects of system variables on film uniformity.

2. Simulation of Metallizing Uniformity

In our research, Idvac utilized MathCad models to simulate aluminium thickness uniformity across nine standard boats, both under stable and fluctuating temperature conditions. Boat temperature fluctuations—often caused by aging, poor electrical contacts, poor cooling or varying power levels—can significantly affect the evaporation rate, leading to inconsistent coating thickness across the web.

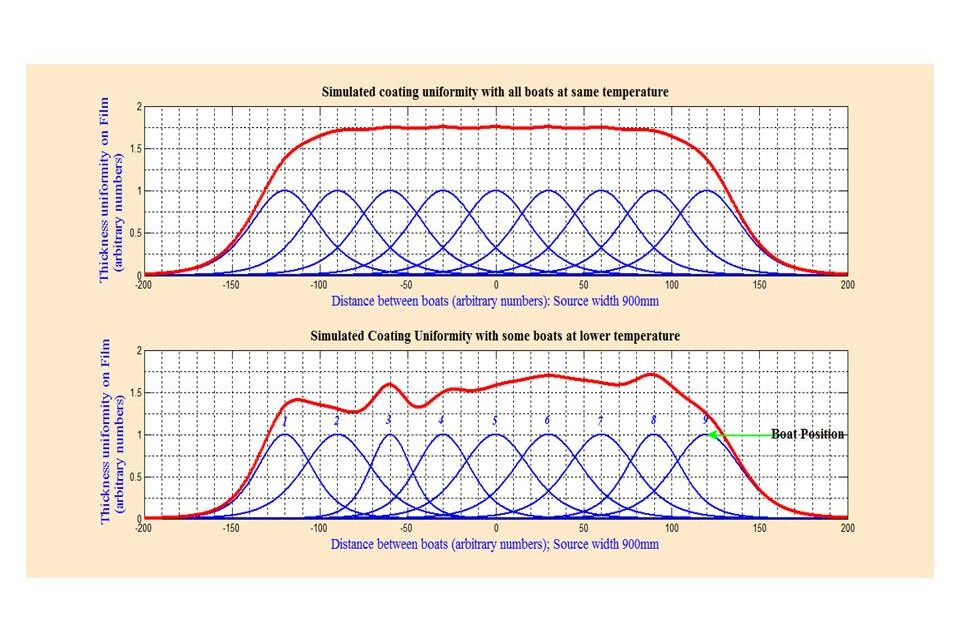

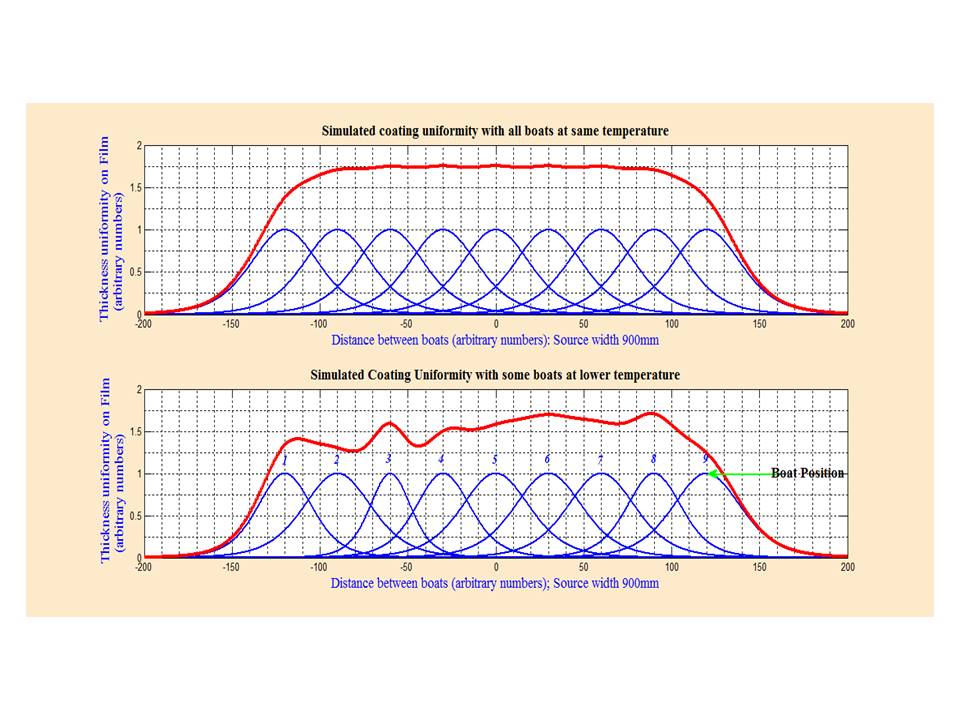

The simulation clearly shows that any fluctuation in boat temperature will disrupt uniformity, resulting in banding effects. Figure 1 illustrates the simulation results, comparing stable and fluctuating boat temperatures, emphasizing how these variations influence coating consistency.

Figure 1: Idvac Simulation of Metallizing Uniformity

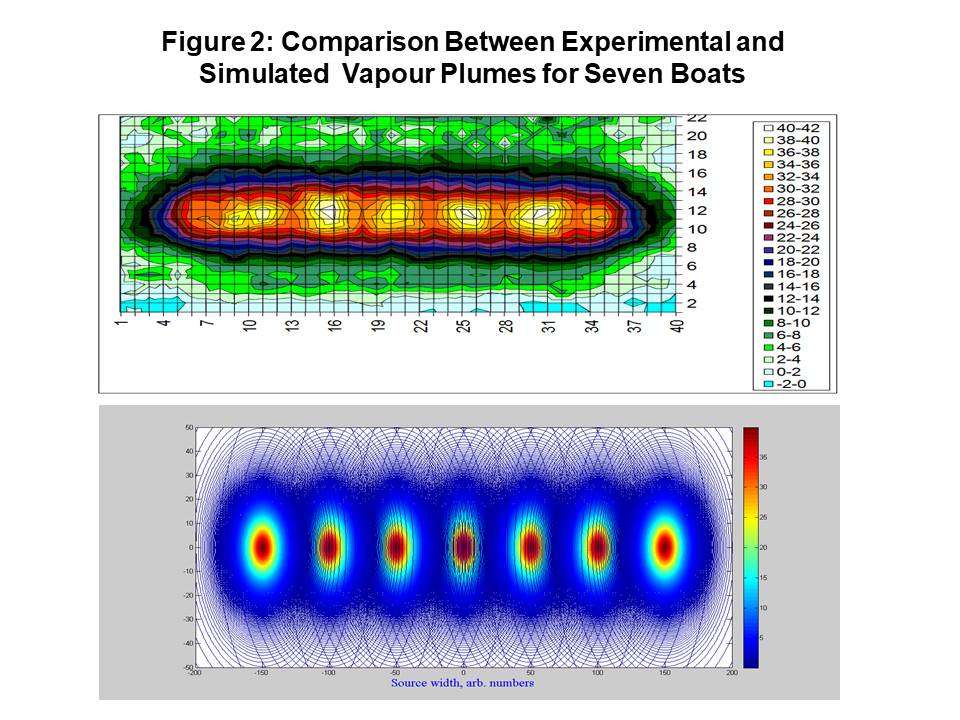

To further refine the model, we also simulated the interaction between vapor plumes from multiple boats at high evaporation rates. The simulation demonstrated that higher vapor pressures cause significant interactions between the vapor clouds, distorting the plumes and affecting coating uniformity. Figure 2 compares the simulated vapor plumes from seven boats with experimental data provided by General Vacuum Ltd, showing a strong correlation between predicted and measured results.

| Figure 2: Comparison Between Experimental and Simulated Vapour Plumes for Seven Boats |

3. The Role of Boat Condition in Uniformity:

Our simulations indicate that the number of boats used, and their operational conditions directly influence the uniformity of the metallized film. While using more boats can improve uniformity across the web, it’s essential that the boats operate under stable conditions. Boat aging, temperature fluctuations, and power inconsistencies can cause some boats to behave in a focused manner (higher evaporation rates) while others may disperse vapor flux more broadly (lower evaporation rates), leading to uneven coating distribution.

To ensure optimal results, it’s crucial that all boats provide the same evaporation rate. Maintaining consistent boat conditions, temperature control, and system stability is essential for achieving high-quality, uniform coatings.

3. Conclusion:

Achieving uniform coating thickness in vacuum web metallizing has become increasingly challenging due to the demand for faster production speeds and higher-performance coatings. To meet these demands, it is critical to optimize factors such as boat condition, evaporation rate, and system stability. At Idvac, we’ve leveraged MathCad simulations to predict and enhance the impact of aging boats on metallized film uniformity. We’ve also modelled the interaction between vapor clouds from multiple boats, which has proven to be highly effective in achieving improved coating uniformity.

The MathCad simulation model can also be used to assess how factors like gas pressure and source-to-substrate distance affect aluminium thickness uniformity, offering predictive insights that can guide optimization efforts.