The Future of Copper Metallization in High-Tech Applications: Market Trends and Key Challenges

March 5, 2025As we move towards more advanced electronics, telecommunications, and medical devices, copper metallization is becoming a key component in numerous high-tech applications.

The Surge in Demand for Copper Coated Flexible Films

Copper metallized films are gaining momentum due to their exceptional conductivity, flexibility, and cost-effectiveness. These films are essential in a variety of applications, from flexible electronics and circuit boards to RFID technology and automotive sensors. As industries demand more energy-efficient solutions, copper’s high conductivity and thermal performance make it ideal for innovations like smart grids, LED lighting, and solar energy solutions.

The Market Growth Potential

According to Future Market Insights Inc, the global copper-coated film market reached USD 3.4 billion in 2024 and is set to grow at a CAGR of 3.7% through 2034, reaching an estimated USD 4.9 billion. Countries like China, India, US and Europe are expected to drive much of this demand, with applications in telecommunications, healthcare, and consumer electronics leading the charge.

Challenges in Copper Metallization: Heat Load on Flexible Films

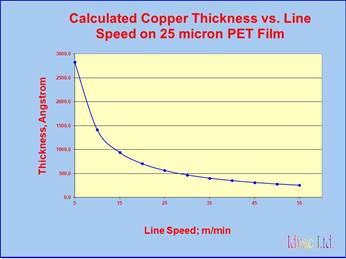

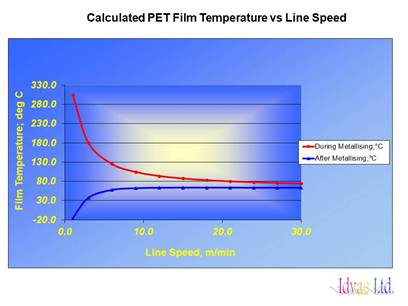

One of the major hurdles in copper vacuum metallization for high-tech applications is managing the heat load during deposition. To achieve thick copper coatings (over 100nm) on ultra-thin films (as thin as 6 microns), it requires a significant increase in evaporation rates or a reduction in film speed during the deposition process. However, this leads to high thermal stresses on the films, especially when utilizing traditional roll-to-roll (R2R) vacuum metallization methods.

Heat load in R2R vacuum metalizing can be broken down into three key components:

- Radiation heat from the evaporation source: 50-60%

- Heat of condensation: 35-40%

- Kinetic energy of evaporated materials: 5-10%

Managing these heat loads is critical, as excessive heat can damage the films and disrupt the deposition process.

Innovative Solutions to Overcome Heat Challenges

Idvac Ltd. has been at the forefront of developing advanced R2R metallizing techniques that address these heat-related challenges. Their approach includes reducing radiant heat from the evaporation source and optimizing the heat transfer from the film to the cooling drum. Moreover, Idvac is working on a unique evaporation source that minimizes radiant heat load without requiring costly power supplies or transformers.

The Road Ahead

The demand for copper-coated films will continue to rise as industries such as telecommunications, electronics, and healthcare adopt new technologies. To meet these evolving needs, innovation in R2R copper vacuum metallization processes is crucial. With the right solutions to heat load management, we can expect continued growth in this market, potentially reaching USD 4.9 billion by 2034.

Connect With Idvac ltd

As the copper metallization market grows and evolves, staying ahead of the curve is crucial. Follow Idvac for more insights into the latest trends in high-tech applications and copper metallization processes.

By exploring new technologies and refining the vacuum metallization process, we can unlock even more potential for copper in emerging markets. Let’s talk about how these innovations are shaping the future…

For further details please contact:

Professor Nadir A G Ahmed

Idvac Ltd

Manchester, UK

Email: idvac@aol.com

www.idvac.co.uk