20% Growth and Strategic Collaborations

February 12, 2025AV Flexologic`s CEO – Martijn Otten – has announced a 20% growth for 2024, achieving just over €30 million turnover on group level. The company expects to maintain similar growth in 2025. To support this upward trajectory, the company is installing new production equipment at its headquarters in the Netherlands to meet the growing demand for its innovative solutions.

Their fully or semi-automatic mounting machines are more popular than ever, especially the latest generations of the SAMM – “SAMM 3.0”, which was launched at the past Drupa, and the FAMM.

For the last 30 years, AV Flexologic has always been at the forefront of flexographic automation, continuously setting new benchmarks for efficiency and precision. The company invented automatic plate mounting technology in 2005 and has since dominated the global market. Over the years, AV Flexologic has continued to lead the industry, delivering groundbreaking innovations that optimize flexo prepress workflows. While others have only recently entered the automatic mounting space, AV Flexologic has spent nearly two decades refining its world-class technology, making its SAMM and FAMM series the most advanced in the industry today.

The company’s strategic collaborations have played a crucial role in this success. AV Flexologic maintains partnerships with major OEM manufacturers, including W&H, PCMC, BOBST, Comexi, and Uteco, equipping their demo centers with AV mounters and having technical integrations. Additionally, a now three-year cooperation with Tetra Pak sees 3-4 of their plants adopting AV technology annually.

Another driver of this growth is introducing package deals that provide converters with comprehensive solutions, such as sleeve storage systems and sleeves from Tech Sleeves. These offerings position AV Flexologic as a one-stop shop for equipping new plants. A premium sleeve variant featuring glass fiber and rubber edges has gained significant traction, particularly among high-end printers.

At Drupa, AV Flexologic unveiled a laser engraving and flexo plate cutting machine “EXACT” as an alternative to Kongsberg.

Automatic Mounting in Flexo Printing

Automatic mounting in flexo printing delivers transformative benefits, enhancing print quality and operational efficiency. By automating the precise placement of printing plates onto sleeves, this technology ensures consistently high-quality prints, free from defects and irregularities. It significantly reduces setup time and manual effort, streamlining workflows and enabling faster job transitions.

Automation also plays a crucial role in ensuring consistency and repeatability, essential for maintaining uniform prints across high-volume production. The ability to adapt seamlessly to different materials and job requirements makes automatic mounting a flexible and indispensable tool for modern flexographic printers. By minimizing waste, lowering labor costs, and improving overall productivity, automatic mounting is no longer just an advantage—it has become a strategic investment for printers looking to maintain their competitiveness in an evolving industry.

Lean Manufacturing and sustainability: Reducing Waste Across the Value Stream

AV Flexologic is committed to lean manufacturing principles and sustainability and actively works to reduce waste in the flexographic printing value stream. By automating mounting, cutting, and sleeve handling, the company helps customers minimize plate waste, reduce material consumption, and optimize production workflows.

AV Flexologic’s internal lean manufacturing strategy has been instrumental in sustaining its growth and reducing lead times. By introducing a kanban system for their standard production line, production times for new machines have been reduced from 20 weeks to just 3 weeks, allowing the company to meet increasing demand while improving quality. Process optimizations have also cut the average man-hours per machine in half, enabling production to scale efficiently.

Customer satisfaction remains a key priority, with ongoing initiatives to reduce warranty-related service visits and expanding their service capacity globally, to be local and close to customers as much as possible. By ensuring its machines operate with the highest levels of reliability and precision, AV Flexologic continues to strengthen its reputation for excellence.

SAMM 3.0: Advancing Automatic Plate Mounting

The SAMM 3.0, launched at Drupa 2024, has proven to be a milestone in the flexographic printing industry, achieving notable success with over 40 units sold already. This latest generation of automatic plate mounters has significantly contributed to AV Flexologic’s impressive growth, while the SAMM 2.0 remains available as an entry-level option at a lower price point.

The SAMM 3.0 offers double the speed and accuracy of its predecessor, thanks to innovations such as a new patented backlight system for image recognition, which illuminates mounting marks from underneath. This enhancement is particularly effective for microdot applications, ensuring precise plate alignment.

With a redesigned mechanical structure, enhanced safety features, and updated software—including Eastmount for intuitive job creation, PDF import capabilities, and a job queue system—the SAMM 3.0 is engineered for high-performance operations. Key features include an automatic vacuum table for secure plate handling and Ultra-HD camera technology for micron-level accuracy. The system achieves mounting speeds of under 30 seconds per plate with an accuracy of 5 microns.

Over 1,500 SAMM units have been installed globally, underscoring the reliability and efficiency of this series, dominating the global plate mounting market with over 50% market share. The SAMM 3.0 is ideal for flexographic printers aiming to meet higher quality demands, handle shorter and more frequent job runs, and achieve faster changeovers. According to AV, it enhances prepress workflows and can achieve a return on investment in less than a year.

EXACT: A Breakthrough in Plate Cutting and Engraving

At Drupa 2024, AV Flexologic also introduced the EXACT Flexo Plate Laser Cutting & Engraving System, a revolutionary alternative to traditional knife-based cutting tables. This new laser based technology eliminates the risks associated with mechanical cutting, ensuring cleaner edges, higher precision, and improved repeatability. Intricate patterns and rounded corners are also unique and now available. Unlike conventional cutting systems, the EXACT can also laser-engrave plates for traceability, seamlessly integrating with AV Flexologic’s mounters to prevent errors and streamline the mounting process. The system’s enclosed design enhances safety while maintaining high-speed operation, making it an essential tool for modern prepress workflows.

FAMM 3.0: A Leader in Advanced Automated Mounting

With over 50 installations of the FAMM 3.0 and more than 200 FAMM systems deployed globally, this advanced automated plate mounting system has become a key solution for large converters managing frequent job changes. In recent years, gang jobs have gained popularity, driven by advancements in 7C Extended Color Gamut (ECG) printing. Converters handling complex jobs with multiple plates benefit significantly from the precision, efficiency, and reduced labor dependency offered by the FAMM 3.0.

Countries with high labor costs or a shortage of skilled workers have seen particular value in adopting automated systems like the FAMM 3.0. While mounting times are comparable to those achieved with the SAMM 3.0, the FAMM’s ability to integrate seamlessly with robotic systems has made it an increasingly popular choice for fully automating mounting departments.

The FAMM 3.0’s precision, achieved through advanced vision technology and micron-level accuracy, is especially crucial for ECG printing, where maintaining consistent color-to-color registration is vital. This automation ensures error-free, high-quality prints while reducing waste, setup times, and operator intervention.

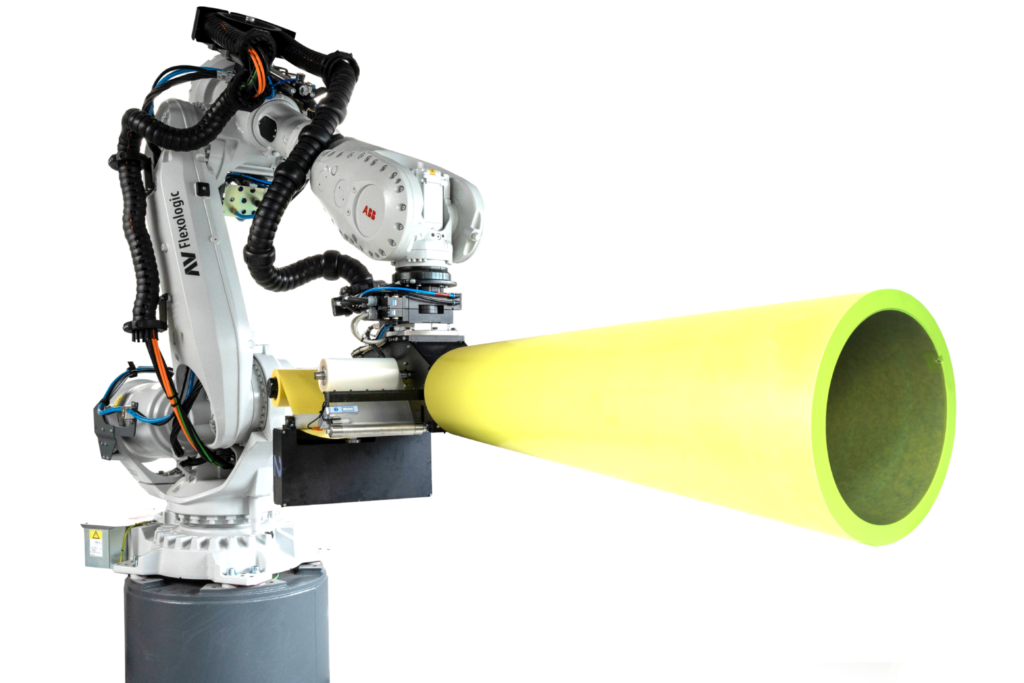

RoboCELL: Revolutionizing Prepress Automation

The RoboCELL is a patented, fully automated system designed to optimize the prepress workflow in flexographic printing. Developed by AV Flexologic, it seamlessly integrates robotic sleeve handling, tape application, and plate mounting, significantly reducing manual intervention and enhancing operational efficiency.

Key components of the RoboCELL include RoboTAPE, which automates tape application with precision, minimizing waste and errors; RoboSLEEVE, a versatile robotic tool for handling and positioning sleeves safely; and the FAMM 3.0.

Looking Ahead: Growth, Innovation, and Customer-Centric Solutions

With a focus on automation, strategic partnerships, and customer-driven innovation, AV Flexologic is well-positioned to maintain its 20% annual growth trajectory. Future investments in workflow optimization, equipment reliability, and enhanced customer support will further drive industry leadership and ensure that AV Flexologic remains at the forefront of flexographic printing technology.

By combining cutting-edge solutions with strategic expansion and operational excellence, AV Flexologic is shaping the future of flexo prepress, setting new benchmarks for efficiency, precision, and automation.

Website: www.flexologic.nl