The right dieboard for every requirement

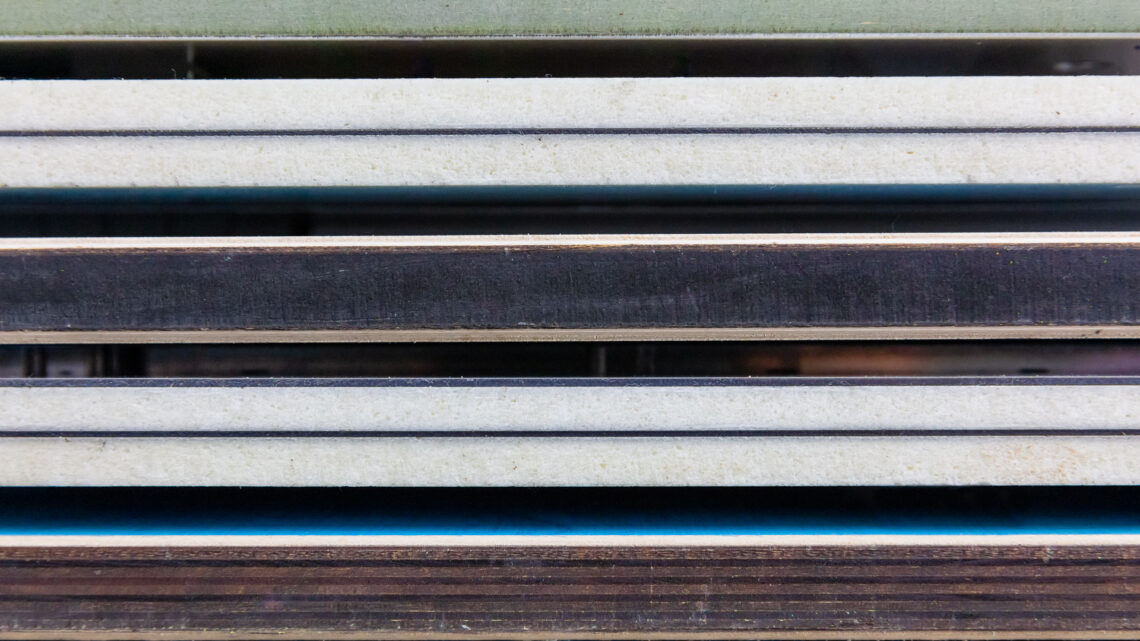

March 23, 2022The globally operating diemaker Marbach, offers a comprehensive portfolio of dieboards. Depending on the customer’s requirements or the respective order, a suitable dieboard material is available. The dieboard forms the basis of a cutting-die. The contours of the packaging are first inserted into a plate made of various materials. Then the knives and creasing rules are positioned, and finally the appropriate rubber is applied. There are dieboards for standard requirements as well as for ones with higher demands on durability and accuracy. For standard requirements, Marbach offers two wooden dieboards: Multiplex and greenplate. For more exacting requirements dimensionally stable dieboards are available. Their material selection and structure ensure that they remain dimensionally stable even under hygroscopic influences and strong climate fluctuations. These include the Marbach solidplate as well as various duramar versions.

Multiplex dieboards.

Mulitplex dieboards are made of high-quality birch wood. They have excellent lasercompatible properties and are therefore ideal for the base material of a cutting-die. The crosswise gluing of several wood layers gives the multiplex dieboard the stability it needs and ensures a long lifespan.

Marbach greenplate dieboards.

If you attach particular importance to ecological sustainability and security of supply, you should choose Marbach greenplate when selecting your dieboard. This is because this dieboard consists of 30% of primary raw material birch and 70% of secondary material. Like the multiplex dieboard, Marbach greenplate has excellent laser-compatible properties. It means low set-up times, high machine speeds, excellent storage stability but also security of supply and ecological sustainability.

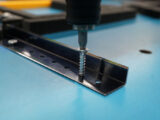

Marbach solidplate dieboards.

The Marbach solidplate is the entry-level product in the dimensionally stable dieboards category. The solidplate is based on two steel plates which are applied to the proven Marbach greenplate core. Thanks to its steel surface, this design allows quick and easy rubber replacement. For long runs, multiple knife changes are possible.

Marbach duramar dieboards.

The dieboard made of duramar is the flagship in the dimensionally stable dieboards category. Here, glass-fiber-reinforced plastic is combined with steel plates. Depending on the combination of these elements, different versions of the duramar dieboard are available: eco, plus or performance. These dieboards are also non-hygroscopic. They are characterized by their high dimensional stability and extremely long lifespan. They can be frequently re-knived and have an enormous register accuracy, even with large machine formats.

Aluminum dieboards.

The aluminum dieboard meets the most special requirements. It is not only stable, but also has high thermal conductivity. This makes it ideally suited as a heatable dieboard. It is mostly used for special materials outside of packaging, such as for die-cutting and creasing plastic. But it is also used for the most demanding hygiene requirements.

Bernhard Reisser, industry manager at Marbach for the paperboard sector: “Our dieboards are as individual as our customers’ needs. Together with our customers and depending on the order, layout, run length and requirements, we select the suitable dieboard. This ensures optimum die-cutting results and maximum performance in the production of the packaging. Our customers are thus assured that they are using the tool that is perfectly suited to their requirements. And so the best possible results are guaranteed.”