The light way of blanking

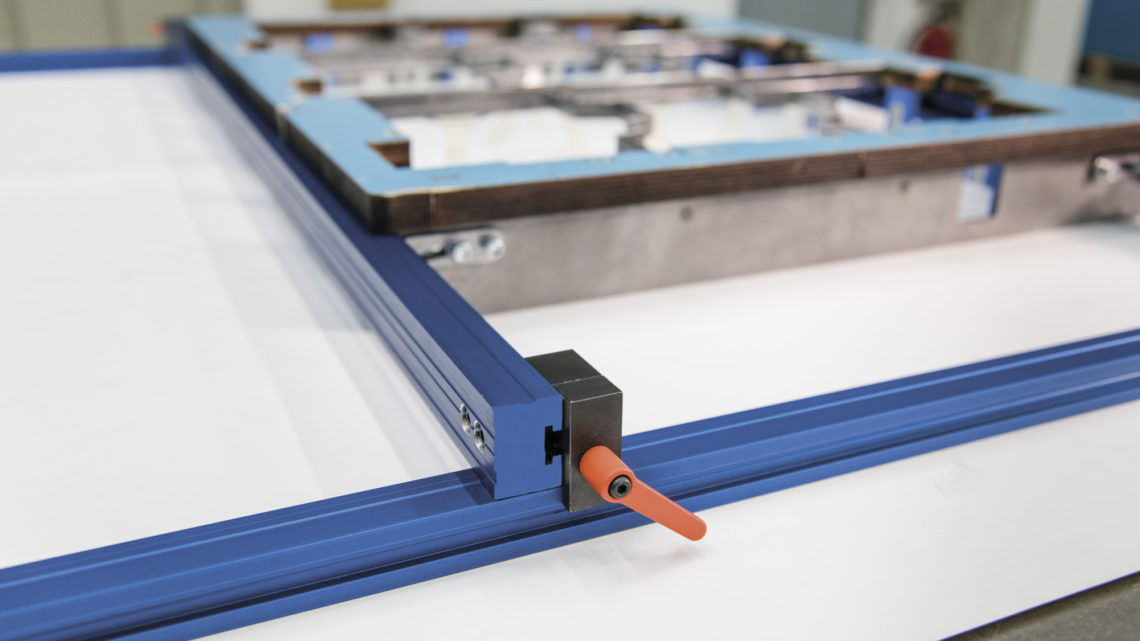

October 30, 2019The Heilbronn-based die-manufacturer Marbach, offers various solutions for blanking, which can be individually selected according to customer requirements and technical necessities. Under the names compact blanker, marbablanker and lightblanker, Marbach offers a range of tool solutions. In trend is Automatic blanking. Compared to manual separation, it brings increased productivity to the entire postpress sector. In addition, it ensures precise stacking of blanks or paperboard sheets. An existing blanking unit in the machine should therefore be used as often as possible for reasons of efficiency. In this way the efficiency of further packaging processing is increased. Thus saving time for the user and consequently lowering costs for the packaging manufacturer. Marbach sales manager Bernhard Reisser: “We work with a modular system for blanking. This means that our solutions are quickly available and we can react very flexibly to our customers’ requirements. Our systems are all ready-to-use, so that they can be easily and quickly installed in the blanking station without long set-up times.” The lightblanker The lightblanker is a modular blanking tool in which the base frame can remain in the machine. It can be quickly and easily adapted to the order-specific separating form for any application. Thanks to its quick-lock mechanism, it is immediately ready for use in just a few simple steps. The marbablanker For repeat orders Marbach recommends the marbablanker to its customers. The marbablanker is individually tailored to the customer’s needs and is distinguished by its low weight and high stability. The marbablanker ensures short set-up times because the tool frame is individually designed for each order and firmly attached to the actual separating form.