The eSR2F 110, a sustainable and productive solution

December 18, 2018|

The eSR2F 110, a sustainable and productive

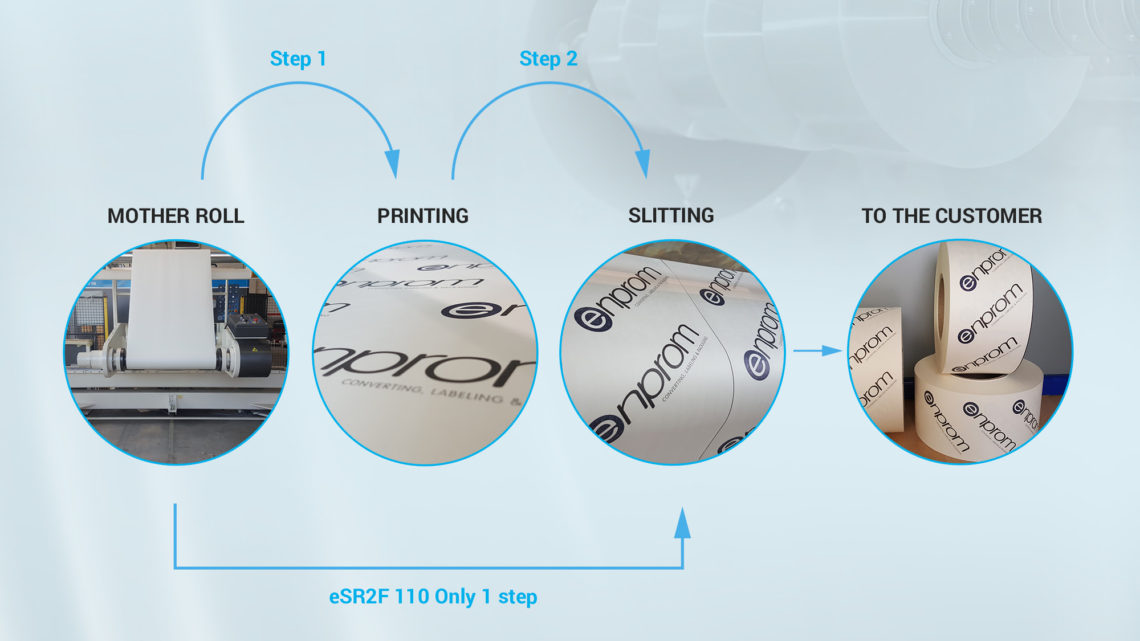

solution The eSR2F 110 is one of the latest innovations in the Hybrid Converting field offered by Enprom; which combines inline processes to offer the best solution. This is obtained by integrating the two conventional independent processes of printing and cutting in a single line to be able to make the final product in a single step. |

|

The result of this merger generates

competitive advantages to the customer such as: waste reduction,

minimum electricity consumption, fewer operators, optimization of the

production area, and ease of production control; thus obtaining a customized

machine, highly productive and innovative in the market, providing added

value and differentiated. The composition of the machine includes: • A regenerative motorized unwinder, which reuses the energy created to feed the other motors. • Perfect high sensitivity tension control by pneumatic dancer roller. • Threading the material by chain. • Two groups of flexographic printing Gearless, CNC. • High performance drying unit with recirculation. • Circular cutting system with printed line inspection. • Assistant for reel discharges with gravitational equipment for extraction of the rewinder shaft. • Regenerative high-performance control equipment. It includes 4.0 technologies. • Intuitive software that is easy to use and controls productivity. |