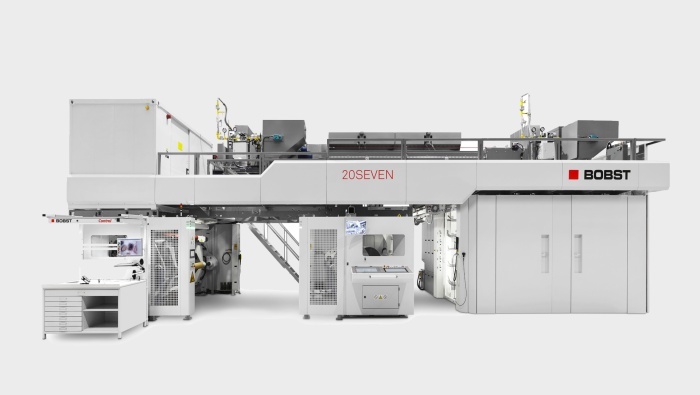

New BOBST 20SEVEN: Designed with extended gamut printing requirements in mind

June 13, 2018Earlier this year Bobst launched a CI flexo press dedicated to 7-colour extended gamut printing. 7-colour

printing, extended gamut printing or fixed colour palette printing describe an optimised printing process

with a set of colours (usually CMYK and Orange, Green and Violet) that promise cost and time savings to

printers, thus making the run more efficient.

New features of the 20SEVEN include the Full Surface Matrix dryer, the smartFLO inking system and the

triLock bearing system. The dryer is designed for a more even distribution of hot air, thus enables excellent

drying at high speeds with reduced temperatures, which is especially of use when printing with water-

based inks. The inking system is optimizing the temperature and flow of ink, deliver predictable, stable and

controlled printing results with both solvent-based and water-based inks.

Most likely the most important new feature is the triLOCK system which according to Bobst completely

eliminates vibrations, even at highest printing speeds. The bearing system features a patented 3 point high

torque locking mechanism driven on opposite linear guides.

The 20SEVEN press can be customized to special production requirements with a number of options such

as downstream flexo units, gravure printing units and turning bars for reverse printing.

According to Bobst Bielefeld a number of Bobst 20SEVEN have already been sold. In the future we will visit

at least one customer in order to ask him about his motivations to buy this new press, and his experiences.

Bobst has produced a video about the 20SEVEN which you can watch here