Optimizing Relief Height: First-Place 2018 FFTA Rossini Scholarship Recipient’s Research on FIRST Relief Guidance

August 18, 2019This study examines the issue of relief depth for flexographic printing plates. Smaller dots supported by less plate relief than the current standard is hypothesized to be more stable and to print with less gain on press due to more structure.

I observed the effects of a decreased plate relief on the highlight dots across three different conventional screenings and one hybrid screening. Reliefs of 0.010-in., 0.014-in., 0.018-in., 0.022-in., 0.026-in. and 0.030-in. were targeted.

On press, variables of kiss impression and over-impression were introduced to the test process. The metrics of density and dot area were analyzed after samples were taken from each run. It was found that there was a positive correlation between density and dot area in relation to each relief and linescreening combination, although as overall ink volume decreased, the printed dot area decreased in the highlights and maintained volume in the shadows.

Variation between shoulder angles of all dot sizes was found. Lower reliefs were found to have slightly greater shoulder angles in highlight dots, compared to the highlight dot shoulder angle of plates with greater reliefs. Lower plate relief depths were found to provide less dot gain and more accurate linear dot output across multiple ink volumes. The plates with 0.009-in. and 0.012-in. relief depth had the least amount of gain across the highlights, much less than the standard reliefs.

2% Dot Shoulder Angles Across Relief

Problem & Purpose

The relief standard of 0.018-in. to 0.020-in. is a well-known Flexographic Image Reproduction Specifications & Tolerances (FIRST)guideline that is followed by many printers. New technologies have enabled much smaller highlight dots and higher-resolution features, and press technologies have improved impression control as well. In light of these changes, it is reasonable to re-examine the optimal relief depth for thin plates (0.067-in.).

Modern printers desire higher linescreens and smaller minimum dots, but are limited with the FIRST guideline for plate relief for thin plates (0.067-in.), used for flexible film and narrow web printing. They are limited due to the lack of support for the highlight dots, which leads to irregular dot geometry while printing. The relief standard does not provide sufficient support in the highlight areas (1 percent to 10 percent dots), which causes these dots to drop off of the plate or not print consistently.

The main problem printers face with deviating from the relief standard is they are worried about printing the floor of the plate with increased impression. However, if the amount of plate relief is decreased, the thickness of the floor could provide more stability for highlight dots, allowing smaller min-dots to be held and vignettes to be smoother. With the current technology available, deviating from this standard to maintain a highlight dot without printing the floor should be achievable. Of course, one cannot focus solely on highlight reproduction. The optimized relief depth must also support shadow reproduction.

The objectives for this project were to maintain a stable minimum highlight dot while successfully decreasing the relief of the plate. The results were compared on film, as plastic is the primary substrate for the flexographic industry, making up around 76.2 percent of the substrates used in flexo. Primarily, this project was based on label work (as it is narrow web), but it would be beneficial to compare the performance of the dots on both paper and film. Also, the stability of minimum dots in relation to the composition of various graphic elements with both conventional and hybrid screening was evaluated.

25% Shoulder Angle Across Reliefs

Hypothesis

This study was designed to answer the question: “Can highlight reproduction be enhanced by optimizing the relief depth of 0.067-in. flexographic photopolymer plates?”

It is hypothesized that if the plate relief is decreased, the shoulder angle of the highlight dots will increase, providing more stability during printing as measured by empirical data from print features, such as tonal scales and vignettes. This will allow printers to print higher linescreens and hold smaller dot percentages without fear of printing the floor if the impression is increased. Otherwise, the null hypothesis is that there will be no significant change due to relief in the highlights, with undesirable amounts of dot gain in the shadows and mid-tone ranges.

Plate Making

MacDermid Graphics Solutions RAVE 0.067-in. photopolymer plates were exposed on an Esko XPS Crystal exposure unit and imaged on an Esko Crystal CDI imager. Extensive back exposure testing took place in order to determine the back exposure energy needed to reach the target reliefs: 0.010-in., 0.014-in., 0.018-in., 0.022-in., 0.026-in. and 0.030-in. A primary concern was reaching the last relief, 0.010-in., as it requires a significant amount of light energy to expose the plate to this relief. Additional back exposure passes were added to the initial baseline exposure cycle, but it was ultimately found that with each additional pass, the photopolymer became more desensitized as more oxygen is used up during the exposure process.

The limits of the exposure led to a plateau in capable plate relief that topped out at 0.014-in. for most irregular exposure settings. In order to get to the lowest relief, the pixel pass time, number of exposure passes and overall back exposure energy all had to be altered. The XPS was used instead of a conventional bank system to simulate the creation of flat top dots on a conventional plate, rather than using a flat top dot-formulated plate exposed with a conventional UV bulb system.

Two relief window conditions were used to expose the plates to the desired reliefs. One at the “normal” baseline setting, which provided reliefs within the standard 0.018-in. to 0.026-in., and the second at a setting that added an additional pass with increased laser power to provide reliefs from 0.010-in. to 0.018-in. Although the machine was calibrated, the reliefs it provided were not what was intended in the final output. The XPS output plates with 0.034-in., 0.031-in., 0.029-in., 0.028-in., 0.015-in. and 0.013-in. relief values for the first run, and output plates with 0.009-in., 0.012-in., 0.018-in., 0.020-in. and 0.023-in. for the second run.

Each plate was imaged, exposed and washed out on the MacDermid EVO solvent washout and processing unit. After post-exposure and detack, the plates were trimmed down and mounted on a plate cylinder with a repeat of 22-in. The plates themselves were created to be run with a banded anilox roll to see the impact of ink volume on the final print. An HD Benchmark screening test was conducted to determine the intended spot size for the HD screening portion of the plate, along with testing the stickyback durometer in respect to the plate’s durometer. A 13-series stickyback was used. It was also determined that a 12-pixel spot size with a screening of 150 lpi would yield the best HD screening to determine the effect of plate relief.

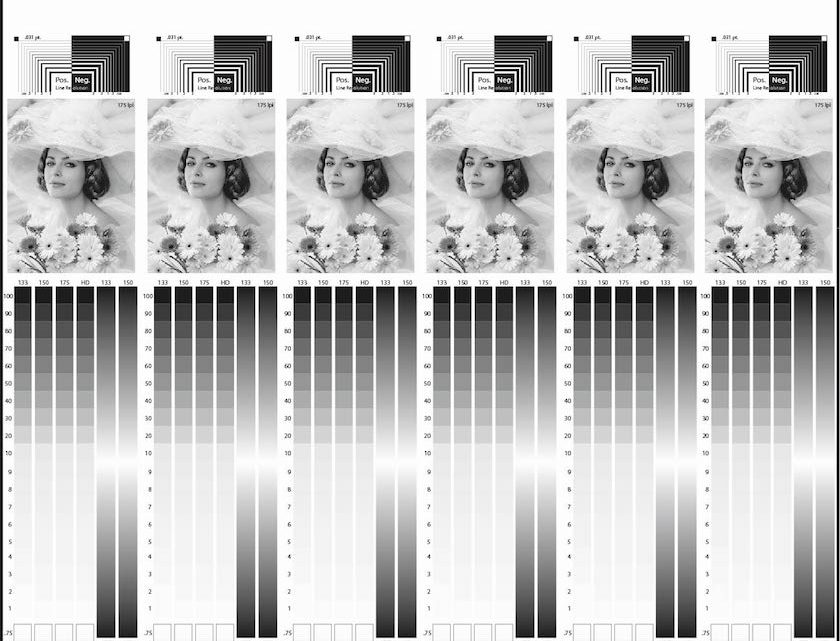

Each plate contained solid and reversed text of varying sizes, a blank space to provide plate floor vulnerability, a line target with varying line weights—both positive and reverse—a high key image set at a linescreening of 175 lpi, four sets of tint scales measuring from a 1 percent dot to a 100 percent dot at four different linescreenings (133, 150, 175 and HD), linear gradients ranging from zero percent to 100 percent dots and radial gradients measuring from a zero percent to 10 percent dot, a tint scale for highlight dots at the four different specified screenings containing dots at 0.75 percent, 0.50 percent, 0.25 percent, and 0.15 percent (see Figure 1). In addition to these tint scales, a microtype target was created with text ranging from 0.1 type to 0.5 type in both serif and sans serif fonts. A small line target was created ranging from 0.006-mm. to 0.10795-mm. increasing in increments of 0.006-mm. to test the capabilities of the imager on a micron level.