Maintenance – really necessary?

May 24, 2020No company wants to spend money without necessity – but when is maintenance really useful?

In general, there are three different types of maintenance:

- If problems have already occurred, repair maintenance (or also restauration or corrective maintenance) is usually unavoidable for recovery.

- If you want to avoid unplanned breakdowns, you invest in preventive maintenance, which is usually carried out at predetermined intervals.

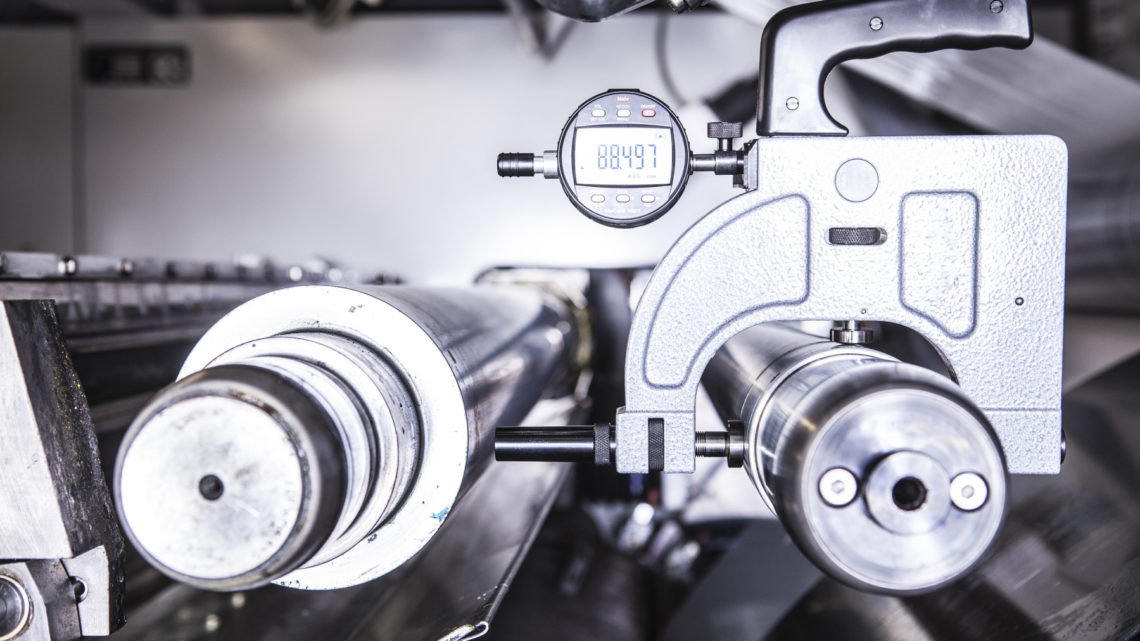

- Prediction maintenance is the further development of the preventive maintenance. Using the latest technology, the essential components are checked and the measurement data analysed to determine the required maintenance intervals.

Repair maintenance is still the most widespread, but it is also the most expensive and usually involves enormous downtimes. Preventive maintenance, on the other hand, not only prevents press downtime but also improves print quality and the condition of the machine. It is therefore the most effective maintenance method and is already being strategically used regularly in many companies. Less well known and established to date is prediction maintenance where scientific data analysis determines the maintenance intervals.

How to identify the need for maintenance?

Ideally, there is no need. If problems such as sticking adapters, leaking shafts, difficulties with clamping, long set-up times or even downtimes occur, the only remaining option is repair maintenance. In order to ensure reliable availability of the system, extend its lifetime, minimize abrasion and, last but not least, to ensure the safety of employees, the system should be serviced regularly – preferably at one or two-year intervals – as a preventive measure.

Maintenance despite Corona?

Not an easy question that every company must weigh up for itself. As a precaution, many companies postpone their 2020 annual maintenance until the third or fourth quarter – when things could get tight with available service dates. The best thing to do is to speak to your service provider as soon as possible and reserve an appointment.

After all, systematic maintenance can save considerable amounts of money, material and working time in the long term. That’s why regular maintenance makes perfect sense – and is otherwise urgently required at the latest when the first repairs have to be made due to missed maintenance.

Contact SWT Services for further information under info@swt-services.com