Idvac Develops Vacuum Deposited Polymer Nano-Layer To Protect Metallised Copper

August 25, 2019Idvac Ltd., a UK vacuum R&D specialist, is introducing a new innovative product to the security, decorative, packaging, agriculture and solar market. The new product is a vacuum deposited nano Polymer layer to protect vacuum metallised Copper films.

Recent interest in copper metallization is mainly due to its optical, structural, functional and anti-bacterial characteristics. This opens the door for new market applications. This includes holographic embossed Films metallised with Copper, Copper metallised textiles ,RFID ,etc

For security applications, there are two main reasons for the introduction of copper metallisation of holograms as an alternative to standard silvery coloured aluminium; the first is the bright lustre of the Copper, which is difficult to be replicated by using standard aluminium metallising with chemical pigments or dyes, and the second is the de-metallizing of copper, which is somewhat harder than the de-metallizing of aluminium. In the de-metallizing process the metal is removed by chemical or physical process to print letters, logos or patterns within the metallised side. De-metallizing adds another feature to the security hologram to fight counterfeiting. The other added advantage is the electrical conductivity of copper, which could be used for other applications including electrically conductive Textiles, Flexible Printed Circuit boards, Sensors, EMI shielding and RFID antenna.

However, when exposed to the atmosphere or handling, metallised Copper start to tarnish slowly. In a warm, salty, humid environment Copper start to corrode and detach from the film. When Copper is exposed to humid neutral salt a layer of Cu2Cl(OH)3 can build up during reaction with OH– and Cl– to form a green transparent compound. Eventually, this will affect the lustre and durability of the Copper metallised film.

There are many methods to protect the surface of metallised Copper. However, such methods may interfere with the appearance of Copper or affect the electrical conductivity of the metal. Also, some methods use relatively high cost materials. Furthermore, adhesion of some protective coatings onto metallised Copper can also be a problem.

Idvac new process involved the utilisation of a special Polymer that can be vacuum deposited as a nano layer onto the Copper metallised film to form a thin transparent protective layer. The vacuum deposited Polymer nan0-layer is applied using a standard thermal evaporation vacuum R2R metalliser with a special designed evaporation source. It can also be applied as a wet coating using gravure or application equipment. The final product is highly adherent and has a bright finish.

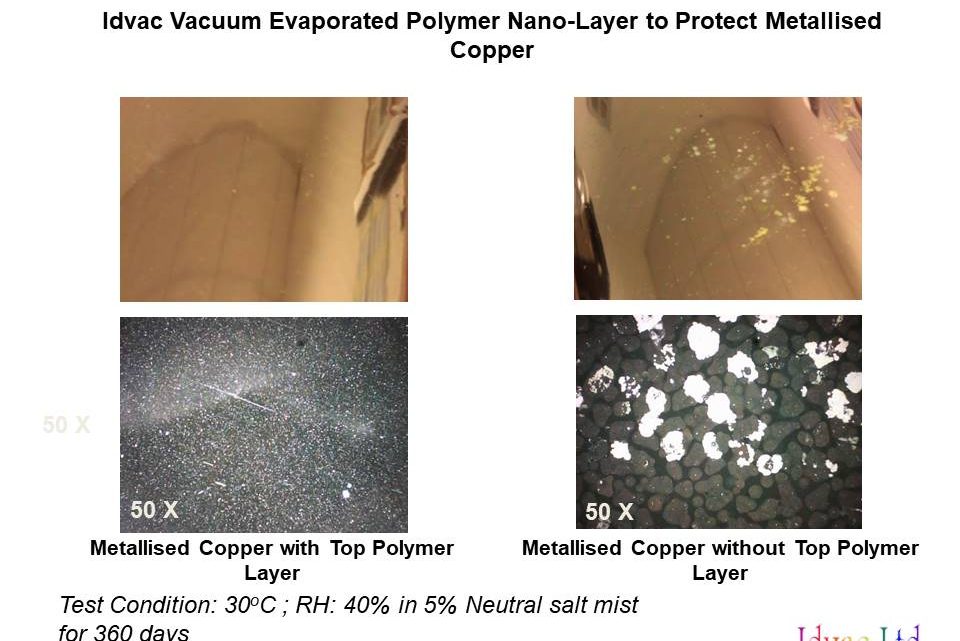

Idvac corrosion testing of the deposited polymer on Copper metallised film shows good durability against humid neutral salt mist. In this test, Copper metallised films with and without the nano Polymer protective layer have been tested using 5% Sodium Chloride neutral salt mist at 30o C and 40% RH for 360 days. The attached figure shows the result of the corrosion testing and indicates the durability enhancement of the Polymer coated Copper metallised film. Other accelerated corrosion testing carried out by our customers at high temperature and humidity level showed similar results.

The main features of this new Polymer vacuum deposited coating are:

1- Thin, adherent and transparent nano Polymer layer is deposited in vacuum using a purpose designed evaporation source.

2- The Polymer has antibacterial and antifungal properties.

3- The Polymer can be applied onto flexible films using a standard R2R vacuum metalliser or as a wet coating using conventional printing machines such as gravure, flexo, etc.

4- The Polymer is vacuum deposited at low temperature and high line speed.

5- The Polymer nano-layer has a smooth finish.

6- The Polymer can act as a UV absorbing material.

7- The deposited Polymer onto Copper metallised film can enhance the durability of Copper against humid 5% neutral (NaOH) salt mist.

8- The nano Polymer layer does not affect the surface electrical conductivity of metallised Copper.

.

Applications

1- The product can be used for the production of durable Copper metallised textiles or on holographic embossed films for security or non- security products including hot stamped labels. Banknotes, Pharmaceutical, etc.

2- The product can be used to protect RFID antenna or sensors from oxidation and tarnish.

3- The vacuum deposited Polymer nano layer can be used for optical applications including heat reflectors and solar window films.

4- The thin Polymer nano-layer can be used for its antibacterial and antifungal properties.

5- The thin Polymer nano-layer can be used as UV absorber for films and textiles.

Since its foundation in 2004, Idvac Ltd. has been successful in researching various markets including holographic, packaging and solar window films. This is done by developing processes and introducing innovative vacuum process know how and technologies for various products. Idvac offer R&D services to develop new innovative vacuum coatings or processes for its customers.