GAMA International will launch its G1000 automatic Ink Quality Control system at K 2019

August 28, 2019GAMA International will launch its G1000 automatic ink quality control system at K 2019 in Dusseldorf, 16th-23rd October, at Hall 10, stand H26. For the company, the G1000 represents its top of the ink control systems line, fully customizable.

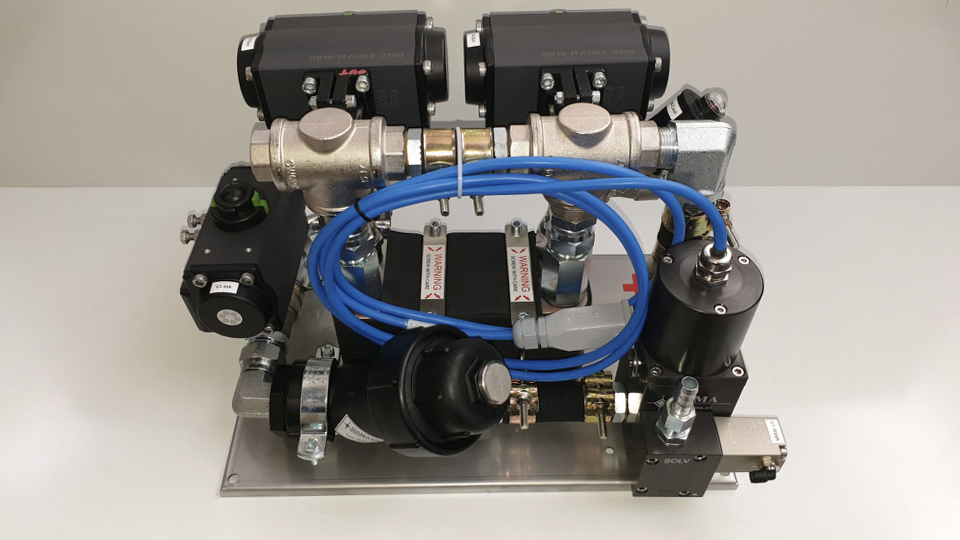

The G1000 has been developed to keep ink quality stable during the printing process and to reduce solvent and ink consumption. It’s not a simple viscometer, it is a complete automatic system, equipped with viscosity and temperature control, magnetic filter, and sophisticated production controls and customized for each rotogravure machine.

This new system displays several advantages: the viscosity and temperature control of ink allows to reduce the use of solvent and ink, quicker start-ups and waste reduction. Furthermore It reduces ink blade lines, thanks to magnetic filter, attracting steel filings. All those features help making the printing process more productive and efficient.

«Thanks to the adoption of a new heat exchanger, we have achieved remarkably higher performances than previous solutions in stabilization of ink temperature», says Sante Conselvan, Sales Director of GAMA International. «Based on tests carried out during production at different temperatures, a minimum saving of 10% of ink and 25% of solvent was observed. It was calculated a return on investment in only 12 months.».

In the continuous R&D activity, and during the cooperation with press manufacturers, GAMA has developed a new more compact electronic structure for the G1000, which can be better integrated in the control panels of the press machine.

«We have already installed four fully customized control G1000 systems on rotogravure printing machines», adds Sante Conselvan. «Customers are excited about performances and we look forward to introduce it officially to the entire printing and converting market».