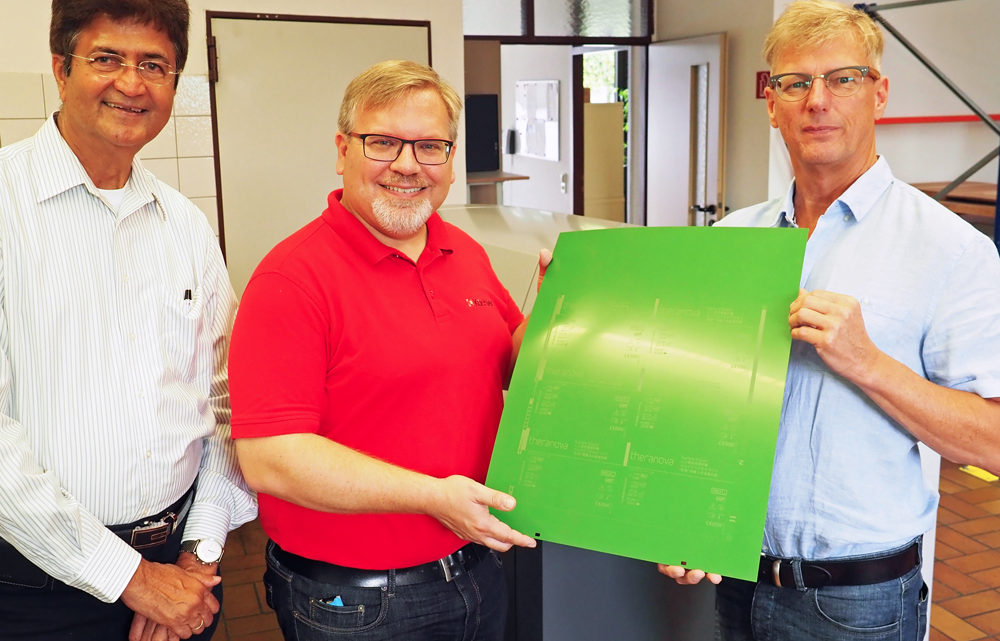

Etiketten-Küchler opts for the predictable and durable waterless plate

September 4, 2019Dirk Handler is an inventive entrepreneur who lives for self-adhesive labels. He runs Etikettenfabrik Erhard Küchler GmbH in Esslingen am Neckar (near Stuttgart), a family-owned company with 44 employees that covers the full range of such products. According to Handler, even though the company doesn’t publisize, the Esslingen experts are more than happy to take on difficult tasks. In the autumn of 2018 all offset output at Küchler was switched to Verico Zahara NWL plates. A significant change it might have been—but difficult, it wasn’t.

Etikettenfabrik Küchler has been operating for 55 years, having been founded in 1964 by Dirk Handler’s grandfather Erhard Küchler. Currently, it runs a single shift and is almost exclusively a producer of self-adhesive labels. It first moved into offset around ten years ago with Codimag presses and their simple but smart printing concept: no roller changes, variable length blanket and short ink trains with no ink keys. “This offered an easy way in for the flexo-trained Küchler-Team”, explains Dirk Handler. The second Codimag Viva Aniflo 420 arrived in 2015 and at the beginning of 2019 a third line was added. These presses are complemented by a range of other machines including a Codimag letterpress line.

Leap forward in quality through waterless offset

The Esslingen company’s equipment is configured so that virtually all jobs can be produced inline even when several passes have to be combined. The second of Küchler’s Aniflo 420 presses to arrive has five offset units, a UV letterpress unit and a flexo coater; the first is capable of up to six offset passes as well as flexo, hot foil and relief embossing, whilst the latest addition has five offset units and a flexo coater. This press features an enhanced substrate transport unit that, depending upon the printing length, allows printing speeds to be increased by up to 30 percent.

The move into waterless offset around a decade ago brought Küchler “enormous gains in terms of print quality and register” recalls Dirk Handler. As an example of what he’s talking about he points to a job featuring blocks of reversed-out text exhibiting extremely precise register despite being five color. Offset has further strengthened the company’s market position but the complexity and quality demands of labels keep increasing.