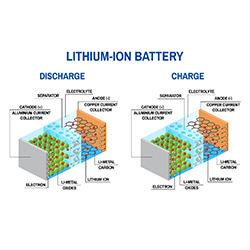

Enercon Releases New Technical Paper on Surface Treatment Used in Lithium-Ion Battery Production

July 11, 2021The global demand for lithium-ion batteries is growing at a fast pace and many of the film substrates used in the production of batteries require surface treatment. Surface treatment enables proper coating adhesion, allowing the batteries to perform as designed.

This new technical article from Enercon reviews important criteria for successful surface treating that enables adhesion without damaging the substrate components of a battery.

“The race is on as manufacturers of lithium-ion batteries look to improve battery performance, keep pace with demand and increase efficiencies, all while reducing scrap,” says Mark Plantier, VP Marketing for Enercon Industries. “The key to optimizing bonding applications of critical substrates is to closely evaluate flame, plasma and corona treaters for the perfect balance of economy, efficiency and performance.”

To assist customers and their evaluation, Enercon offers free laboratory trials.

To download the paper, click here.