Don’t drop a single dot with the new generation of ESA coverings

January 20, 2019Hannecard, as a roller and sleeves covering company established in 1896, has been involved in gravure printing since more than 50 years and has more than 30 years of experience in ESA.

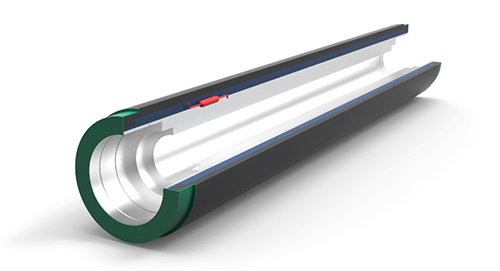

The Hannecard high end coverings for ESA are made of polyurethane. This elastomeric product has tremendous advantages compared to conventional rubbers used in gravure printing for pressure rollers and sleeves : far higher resistance to abrasion, cuts and deformation.

For 3 years now Hannecard has been selling his 2nd generation covering to all type of gravure printers in the world. The ESA range is also adapted to all kind of media and inks:

- HannePearl is the dedicated range for printers in the cardboard industry (www.hannepearl.com).

- HanneCrystal is the range which answers the better for the printing on film and foil.

- HanneVision is the range developed for décor printing and which tends to become the new benchmark in this market.

In each of the tested situations, with representative end-users or OEM the Hannecard ESA coverings gave significant improvements in print quality, life time and safety. Hannecard organized a prelaunch on the market of 300 sleeves and 120 rollers. Even with some failures, which all have been corrected properly, the technical results are now at an unexpected level.

This ESA 2.0 technology has been develop in the dedicated to ESA research and development laboratory based in Switzerland. The process is more than an evolution, it is considered like a revolution. It is kept confidential but we can disclose that it is based on nanotechnologies. The carbon nanoparticles give the electric stability, mechanical resistance. The experience plan has led Hannecard to offer a better chemical resistance. The combination of all these elements makes the Hannecard ESA coverings at the highest level on the market.

In order to support the growth Hannecard proceeded to massive investments to supply sleeves. The group is reaching now more than 400 mandrels to produce in Europe and 150 in Asia.

In 2018, Hannecard invested more than 4 million euros in new machines to increase its capacities worldwide. The plan is to maintain this level in 2019 especially for the coverings of sleeves and rollers used in gravure printing.

These are the reasons why Hannecard is often considered to be the best to be qualified of expert in gravure coverings for sleeves and rollers.