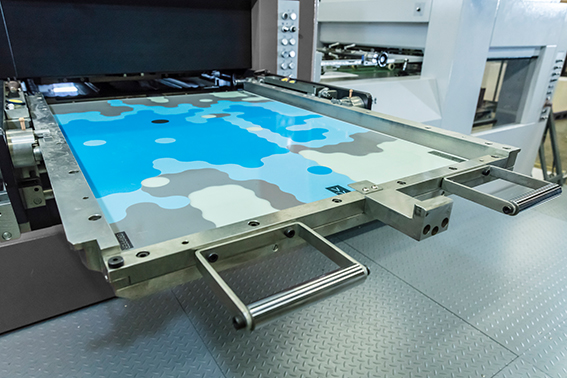

Digital zone levelling DZL|plate now more perfomant

June 19, 2019Since drupa 2016, the Heilbronn-based die-maker Marbach has had digital zone levelling in its portfolio. Almost 400 machines have been equipped with a DZL|plate in the past 3 years. And the number is increasing every day. The DZL|plate is a special protection plate which – individually adapted to your machine – compensates for unevenness in the die-cutting platen. It ensures that a conventional area make-ready – which previously had to be carried out for each individual job – is completely eliminated. Once a digital zone levelling has been set up, it lasts for months. The result: significantly reduced make-ready times for each and every job. To make the DZL|plate even more powerful, Marbach has further optimized it in recent months. Klaus Rommel, Head of Research & Development at Marbach: “We were able to reduce the thickness tolerance of the DZL|plate base plate to a minimum. For example, the tolerance is a maximum of ±0.02 mm, with the dimensional tolerance often being even as small as ±0.01 mm. The DZL|plate is therefore much more accurate than a conventional protection plate.

This higher accuracy means even more make-ready time savings for our customers. And not only that. Thanks to new manufacturing processes, the surface of the DZL|plate is even more resistant to external influences which increases the service life of the DZL|plate.” The DZL|plate can be designed with or without vacuum holes, depending on the machine equipment. This ensures that the performance of the die-cutting machines will also be perfectly utilized with the DZL|plate. Rommel continues: “Although the DZL|plate has a long lifespan, we recommend regular replacement for optimal results. This is because the die-cutting machine gets worn during production. And so the parameters change. For this reason, our recommendation is to check the functionality of the DZL|plate once a year and order a new one if necessary.” In order to guarantee optimal functionality as long as possible, Marbach also has a Marbach DZL|plate special cleaner in its portfolio. This is optimally matched to the properties of the DZL|plate.

For even better performance, Marbach recommends cleaning the die-cutting machine before making an impression for the DZL|plate. Rommel: “It is best to clean your machine regularly with the mplaten|cleaner. Then you will be on the safe side with a clean machine, a clean make-ready and clean results.” In addition to possible optimizations, there is a further innovation in digital zone levelling: The DZL|plate is now also available in format 162.