Apex International Unveils Global Manufacturing Expansion and Staffing Growth

April 16, 2021Apex International announces the implementation of its long-range “Vision: 2020s” plan with significant expansion in each of its five global manufacturing facilities. As part of it’s phased growth strategy, new buildings, new production equipment, and new personnel will enable Apex to scale up production capacity while elevating industry benchmarks for quality. Apex is better positioned to meet increased demand from its flexo, label, and corrugated customer base for reliable, predictable, and durable metering products.

“Based on technology and market trends in the last decade, Apex planned major investments into global facilities and capital equipment to address anticipated industry growth,” reported Marian Waterschoot, CEO of Apex International, headquartered in the Netherlands. “We are pleased to now witness the realization of our ‘Vision: 2020s’ plan. As a result of the packaging industry’s recent growth, our customers require our products more promptly – and our expansion meets that worldwide demand.”

Apex’s Vision: 2020s plan demonstrates its longstanding commitment to continual process improvement. “Apex reinvests 20% of its revenues into product research and development, new equipment, facility expansion, and professional development,” states Apex Chairman Ken Ralton. “Apex is the sole anilox manufacturer to commit such funding for product innovation and R&D. Our mission is as much scientific and exploratory as it is engineering and manufacturing.”

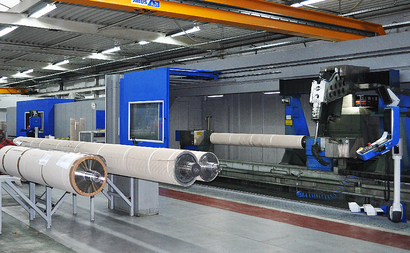

Each of Apex’ manufacturing facilities are in the process of physical plant expansion or receipt of new, state-of-the-art equipment. All new Apex buildings are constructed to ensure energy-efficiency and minimize carbon footprint.

- Apex Italy, based near Milan, is nearing completion on new construction that increases its factory size by 33%. “This expansion allows us to further optimize production cycles and delivery times,” notes Fabio and Stefano Della Torre, Directors of Apex Italy.

- Apex North America, near Pittsburgh, PA, has begun construction planning to double the size of its manufacturing facility and enable a greater warehousing area for its ReadyRoll anilox roll and sleeve in-stock programs. “This long-awaited expansion will give our customers much quicker order turnaround,” affirms Apex North America’s Managing Director Ruud van Cuijk.

- Apex Latin America in southern Brazil will soon take delivery of a new laser which will increase production capability by 25%. Observes Apex Latin America Managing Director Valcinei Bisineli, “This expansion empowers us to meet the soaring demand for flexo and corrugated products in the Latin American market.”

- Apex Asia Pacific near Mumbai, India, recently installed the following new equipment: a laser, a precision CNC grinder, and a latest-technology plasma spray unit which will provide coatings able to withstand the industry’s most demanding environments. These investments to the recently-constructed India facility boost production capacity by at least 40% and will enable the manufacture of larger corrugated and coating rolls. FlexoKITE’s Asia knowledge lab is based here, complete with the latest technology to take artwork from plate to print, host press demonstrations, seminars, and webinars. An additional ten acres of land was recently acquired for expansion of the Apex Asia Pacific facility.